Weng Wai Trading Sdn Bhd

Roofing building materials supplier

Roofing building materials supplier

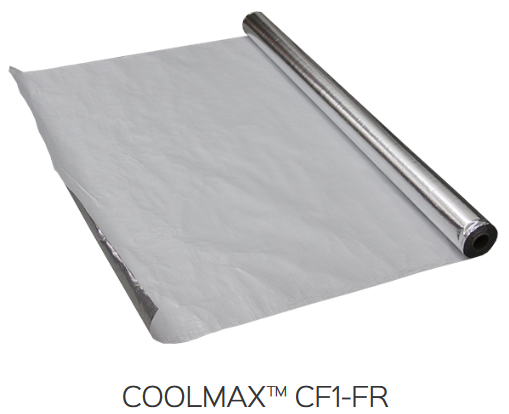

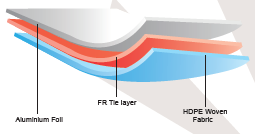

The CF1-FR foil meets your needs for a cost efficient thermal protection and fire safety. Three layers laminate made up of a single sided reflective Aluminium Foil bonded to reinforce high density polyethylene woven fabric by special fire retardant material (FRAL 1).

Dimension per roll - 1.25m (W) x 48m (L)

Coverage - 60 ㎡/roll

Certified by CIDB - MS 2095:2014

| Property | Units | CF1-FR |

|---|---|---|

| Layer Description | Aluminium Foil/FR Tie Layer/FR Woven Fabric | |

| Nominal thickness | mm | ± 0.13 |

| Grammage | Gam | ± 122 |

| MS2095:2014(Sirim) | ||

| Resistance to dry delamination | AS/NZS4201.1 | Pass |

| Resistance to wet delamination | AS/NZS4201.2 | Pass |

| Shrinkage - Machine Direction & Lateration Direction | AS/NZS4201.3 | Pass |

| Tensile Strength - Machine Direction (AS/NZS4301.488s) | kN/m | <9.5 >7.5 |

| Tensile Strength - Lateral Direction (AS/NZS4301.448s) | kN/m | <7.5 >6.0 |

| Edge Tear Resistance - Machine Direction (TAPPIT470) | N | >300 |

| Edge Tear Resistance - Lateral Direction (TAPPIT470) | N | >300 |

| Vapour Barrier (ASTM E96, Procedure B-Wet Cup Test) | μg/N.s | Medium |

| Emittance (ASTM C1371) | e | 0.02 |

| Surface Flame Spread (BS 476:Part 7) | Class 1 | |

| Fire propagation Test (BS 476:Part 6) | Class 0 |

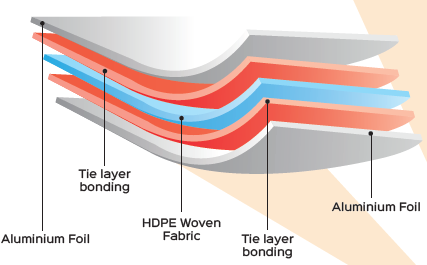

CF2A-FR has 5 layers laminate made up of double-sided aluminium foil, bonded to reinforce high density polyethylene woven fabric by special tie layer bonding material.

Dimension per roll - 1.25m (W) x 60m (L)

Coverage - 73.2 ㎡/roll

Certified by CIDB - MS 2095:2014

| Property | Units | CF2A-FR |

|---|---|---|

| Layer Description | Aluminium Foil/FR Woven Fabric/Aluminium Foil | |

| Nominal thickness | mm | ± 0.15 |

| Grammage | Gam | ± 140 |

| MS2095:2014(Sirim) | ||

| Resistance to dry delamination | AS/NZS4201.1 | Pass |

| Resistance to wet delamination | AS/NZS4201.2 | Pass |

| Shrinkage - Machine Direction & Lateration Direction | AS/NZS4201.3 | Pass |

| Tensile Strength - Machine Direction (AS/NZS4301.488s) | kN/m | <9.5 >7.5 |

| Tensile Strength - Lateral Direction (AS/NZS4301.448s) | kN/m | <9.5 >7.5 |

| Edge Tear Resistance - Machine Direction (TAPPIT470) | N | >200 |

| Edge Tear Resistance - Lateral Direction (TAPPIT470) | N | >200 |

| Vapour Barrier (ASTM E96, Procedure B-Wet Cup Test) | μg/N.s | Medium |

| Emittance (ASTM C1371) | e | 0.02 |

| Surface Flame Spread (BS 476:Part 7) | Class 1 | |

| Fire propagation Test (BS 476:Part 6) | Class 0 |

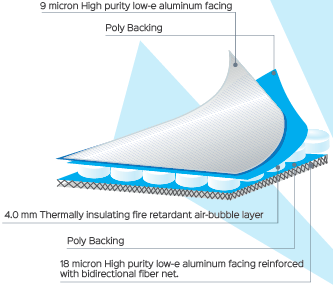

Coolmax SELECT 40+ FR Net (CP3 NET) is a fiber free, thermo-cellular reflective insulation 4.0mm in thickness. It consists of small fire retardant air bubbles and two layers of reflective high resistance pure aluminium surfaces. Emissivity is low(0.03 to 0.05 for each reflective surfaca), and it is reinforced with bidirectional fiber net. The aluminium thickness are 9 micron for top layer, and 18 micro for bottom layer respectively.

Dimension per roll - 1.25m (W) x 50m (L) x 4.0mm (T)

Coverage - 60㎡/roll

10 years warranty

Certified by CIDB - MS 2095:2014

| Property | Units | Select 40+ FR NET (CP3-NET) |

|---|---|---|

| Layer Description | Pure Aluminium Foil/Fire Retardant Heavy Duty PE Bubbles/Bi-Directional reinforced netting 18 microns pure aluminium foil | |

| Nominal thickness | mm | ± 4.5 |

| Bubble Diameter | mm | 10 |

| Emissivity (ASTM C 1371) - Portable Emissivity Meter | 0.03 - 0.05 | |

| Reflectivity | 0.97 - 0.95 | |

| Fire Hazard Properties according to AS/NZ 1530 part 3, 1999 | PASS | |

| Mean Ignition Time | Seconds | 0 |

| Mean flame propagation time | Seconds | 0 |

| Mean heat release integral | Kj/m2 | 0 |

| Mean smoke release | Density/m | 0.006 |

| MS2095:2014(Sirim) | ||

| Resistance to dry delamination | AS/NZS4201.1 | Pass |

| Resistance to wet delamination | AS/NZS4201.2 | Pass |

| Shrinkage - Machine Direction & Lateration Direction | AS/NZS4201.3 | Pass |

| Tensile Strength - Machine Direction (AS/NZS4301.488s) | kN/m | Extra Heavy Duty |

| Tensile Strength - Lateral Direction (AS/NZS4301.448s) | kN/m | Extra Heavy Duty |

| Edge Tear Resistance - Machine Direction (TAPPIT470) | N | Extra Heavy Duty |

| Edge Tear Resistance - Lateral Direction (TAPPIT470) | N | Extra Heavy Duty |

| Vapour Barrier (ASTM E96, Procedure B-Wet Cup Test) | μg/N.s | Medium |

| Emittance (ASTM C1371) | e | 0.04 |

| Surface Flame Spread (BS 476:Part 7) | Class 1 | |

| Fire propagation Test (BS 476:Part 6) | Class 0 |

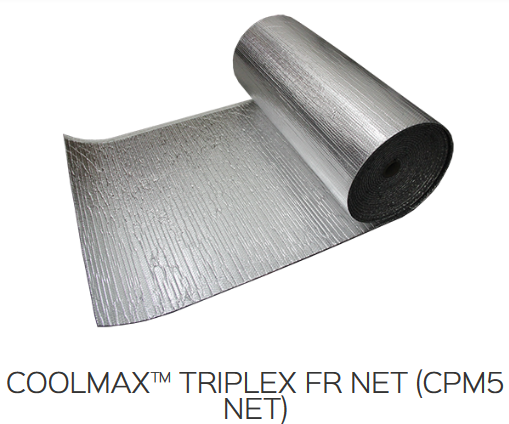

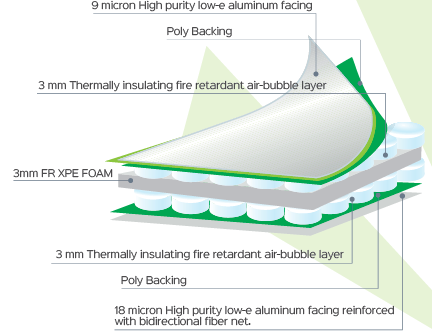

Coolmax TRIPLEX FR NET (CPM5 NET) is made of 2 external pure aluminium foil, covering a double layer of fire retardant polyethene bubble film, a single core layer of XPE fire retardant foam. Emissivity is low (0.03 to 0.05 for each reflective surface), and it is reinforced with bidirectional fiber net. The aluminium thickness are 9 micron for top layer, and 18 micron for bottom layer respectively.

Dimension per roll - 1.2m (W) x 30m (L) x 9mm (T)

Coverage - 36㎡/roll

15 years warranty

Certified by CIDB - MS 2095:2014

| Property | Units | Select 40+ FR NET (CP3-NET) |

|---|---|---|

| Layer Description | Pure Aluminium Foil/FR Heavy Duty PE Bubbles/FR XPE foam/FR Heavy Duty PE Bubbles/ Bi-Directional reinforced netting 18 microns pure aluminium foil | |

| Nominal thickness | mm | ± 9.0 |

| Bubble Diameter | mm | 10 |

| Emissivity (ASTM C 1371) - Portable Emissivity Meter | 0.03 - 0.05 | |

| Reflectivity | 0.97 - 0.95 | |

| Fire Hazard Properties according to AS/NZ 1530 part 3, 1999 | PASS | |

| Mean Ignition Time | Seconds | 0 |

| Mean flame propagation time | Seconds | 0 |

| Mean heat release integral | Kj/m2 | 0 |

| Mean smoke release | Density/m | 0.006 |

| MS2095:2014(Sirim) | ||

| Resistance to dry delamination | AS/NZS4201.1 | Pass |

| Resistance to wet delamination | AS/NZS4201.2 | Pass |

| Shrinkage - Machine Direction & Lateration Direction | AS/NZS4201.3 | Pass |

| Tensile Strength - Machine Direction (AS/NZS4301.488s) | kN/m | Extra Heavy Duty |

| Tensile Strength - Lateral Direction (AS/NZS4301.448s) | kN/m | Extra Heavy Duty |

| Edge Tear Resistance - Machine Direction (TAPPIT470) | N | Extra Heavy Duty |

| Edge Tear Resistance - Lateral Direction (TAPPIT470) | N | Extra Heavy Duty |

| Vapour Barrier (ASTM E96, Procedure B-Wet Cup Test) | μg/N.s | Medium |

| Emittance (ASTM C1371) | e | 0.02 |

| Surface Flame Spread (BS 476:Part 7) | Class 1 | |

| Fire propagation Test (BS 476:Part 6) | Class 0 |

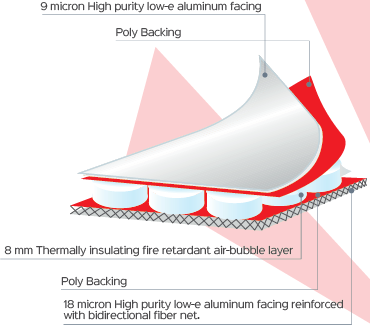

Coolmax SELECT 80 FR NET (CPS5 NET) is made of pure aluminium layers attached to Fire Retardant Polyethylene bubble fim which effectively blocks radiant heat transfer as well as heat conducted throught it.

Dimension per roll - 1.2m (W) x 30m (L) x 8mm (T)

Coverage - 36㎡/roll

15 years warranty

Certified by CIDB - MS 2095:2014

| Property | Units | CPS5-NET |

|---|---|---|

| Layer Description | Pure Aluminium Foil/Fire Retardant Heavy Duty PE Bubbles/Bi-Directional reinforced netting 18 microns pure aluminium foil | |

| Nominal thickness | mm | ± 8.0 |

| Bubble Diameter | mm | 10 |

| Emissivity (ASTM C 1371) - Portable Emissivity Meter | 0.03 - 0.05 | |

| Reflectivity | 0.97 - 0.95 | |

| Fire Hazard Properties according to AS/NZ 1530 part 3, 1999 | PASS | |

| Mean Ignition Time | Seconds | 0 |

| Mean flame propagation time | Seconds | 0 |

| Mean heat release integral | Kj/m2 | 0 |

| Mean smoke release | Density/m | 0.006 |

| MS2095:2014(Sirim) | ||

| Resistance to dry delamination | AS/NZS4201.1 | Pass |

| Resistance to wet delamination | AS/NZS4201.2 | Pass |

| Shrinkage - Machine Direction & Lateration Direction | AS/NZS4201.3 | Pass |

| Tensile Strength - Machine Direction (AS/NZS4301.488s) | kN/m | Extra Heavy Duty |

| Tensile Strength - Lateral Direction (AS/NZS4301.448s) | kN/m | Extra Heavy Duty |

| Edge Tear Resistance - Machine Direction (TAPPIT470) | N | Extra Heavy Duty |

| Edge Tear Resistance - Lateral Direction (TAPPIT470) | N | Extra Heavy Duty |

| Vapour Barrier (ASTM E96, Procedure B-Wet Cup Test) | μg/N.s | Medium |

| Emittance (ASTM C1371) | e | 0.02 |

| Surface Flame Spread (BS 476:Part 7) | Class 1 | |

| Fire propagation Test (BS 476:Part 6) | Class 0 |